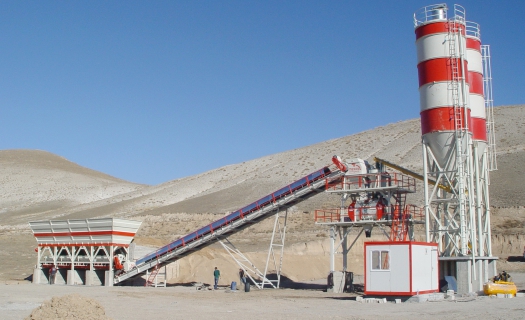

Stationary Concrete Plant Mesas Company ranks among the most preferred concrete manufacturer across the world by its special unsophisticated…

MESAŞ CONCRETE PLANTS

Power Plants and Projects We Manufacture

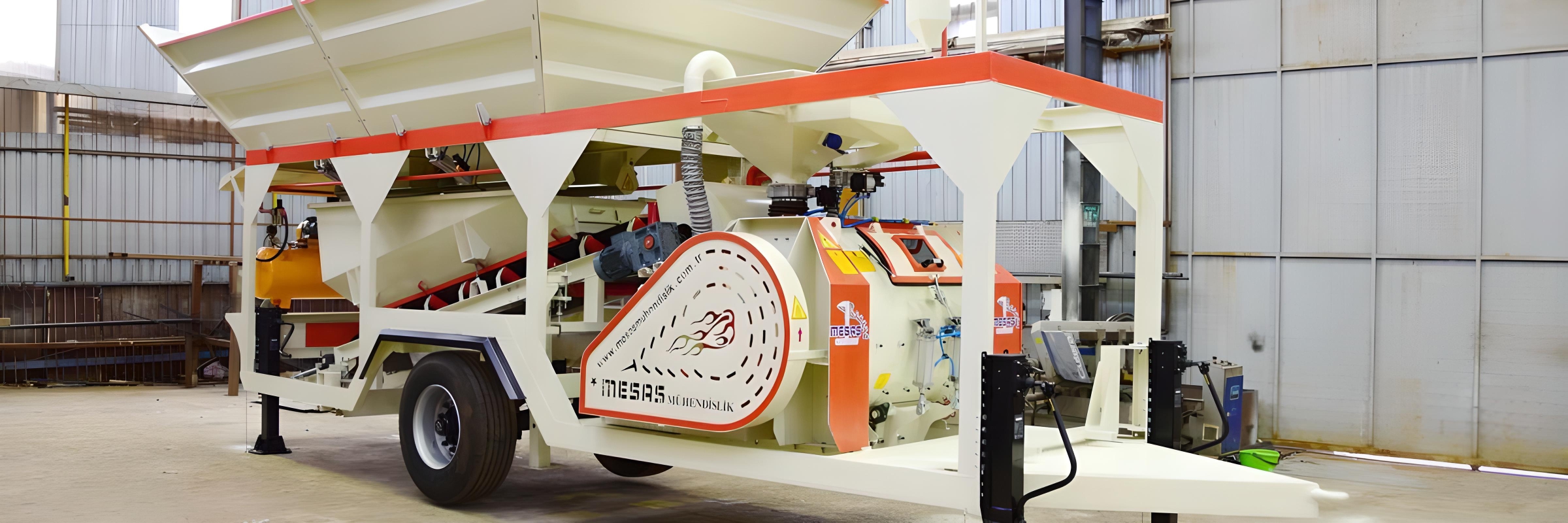

Mobile Concrete Plant

Mobile Concrete Plant Because the transportation costs and foundation concrete requirement are low, it is one of the most preferred plants.…

Dry Concrete Plant

Dry System Concrete Plant Mesaş Engineering, in addition to manufacture of wet system concrete plants, also manufactures dry system…

Economic Concrete…

Economic System Concrete Plants The concrete is produced by weighing the aggregate and cement in the same scale, and water and additive in another…

Compact Concrete Plant

Compact Concrete Plant Compact Concrete Plants are preferred for small-scale concrete production requirements and projects where the cost…

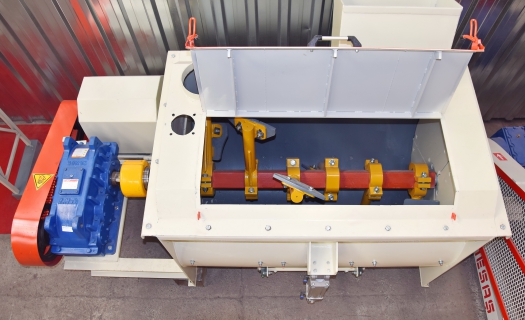

Our Mixers

Single shaft, double shaft and planetary mixers, which are 100% our own production, are used in all our concrete plants.

Special offer

With us

With us

Contact Us